Spin Loader

Overview

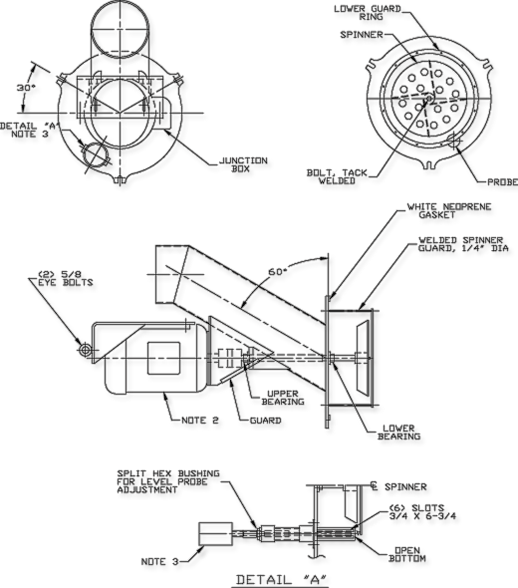

Metalfab's Spin-Loader lets you utilize bulk storage facilities to their fullest capacity. It eliminates the pyramiding which occurs when flakes and granular materials are loaded into bins, hopper cars and piles, and enables you to load up to 15% more product into virtually any storage facility without costly hand labor or interrupting flow. Spin-Loader distributes the product evenly in a 360° arc.

The compact, ruggedly-built Spin-Loader can handle up to 200,000 lbs. per hour of 90 lbs. per cubic foot material. It is simple to install and easy to operate, and may be mounted to the top of the bin or attached to a flexible loading spout and placed inside or over the bin itself. The entering material flows through the tube of the Spin-Loader to a motorized, spinning disc which directs it to the outer walls of the bin, permitting each bin or compartment to be filled to its maximum capacity.

This method of redirecting the particles greatly reduces the possibility of particle segregation, enabling the particles to intermix. And, since the entire loading system may be completely enclosed, product waste and contamination are eliminated.

Features/Benefits

- Available Sizes: Two Models (SL100) 8 5/8" dia. inlet with a 2 HP motor and (SL200) 10 3/4 dia. inlet with a 5 HP motor.

Operating Characteristics

- Loads storage bins and hoppers completely

- Virtually eliminates particle separation

- Saves time and labor

Specifications

Construction

- Carbon Steel

Available Options

- Other Metalfab upstream/downstream bin activators , Convey-All™ Conveyors, bulk bag unloaders, Posibins™ and hoppers

- Bin Activators

- Posibins & Bins

- Bulk Bag Unloader

- Gravimetric Feeders

- Volumetric Feeders

- Conveyors

- Bag Dump Hopper

- Automatic Bag Slitter

- Spin Loader

- Portable (IBC) Bin Unloaders

- Wetting Cone

- Integrated Systems and Subsystems

Activated Carbon Injection

Activated Carbon Injection Dry Solids Processing

Dry Solids Processing Custom Fabrication

Custom Fabrication

Website

Website