Custom Specialty Fabrication

A Wide Range of Capabilities and Product Experience to Meet the Critical Requirements of Today's Design Engineers

Overview

Metalfab's Custom Fabrication facility includes a variety of contemporary metal forming and metalworking equipment along with the latest state-of-the-art plasma cutting machines. Our engineering staff, which has distinguished itself for its many contributions to product improvement over the years, is available for consultation and assistance at the product planning or production stages.

Our skilled technicians, many of whom were trained at Metalfab, average over 20 years of experience working with a variety of metals including stainless steel, carbon steel, and aluminum.

Capabilities

- Design and Engineering

- "Solid Works" 3-Dimensional Solid Modeling

- Custom Fabrication to Customer Specifications Including: metal thicknesses (16 gauge to 1/2" plate), rolling, cutting, stamping, punching, forming, welding, painting, inspection, and assembly

- Mechanical, electrical, and controls drawings in electronic DWG, DXF, and IGES, and “Solid Works� 3D Modeling formats

- Electrical and controls engineering (P&ID, control philosophies, logic diagrams, ladder diagrams, electrical drawings, programming and systems integration

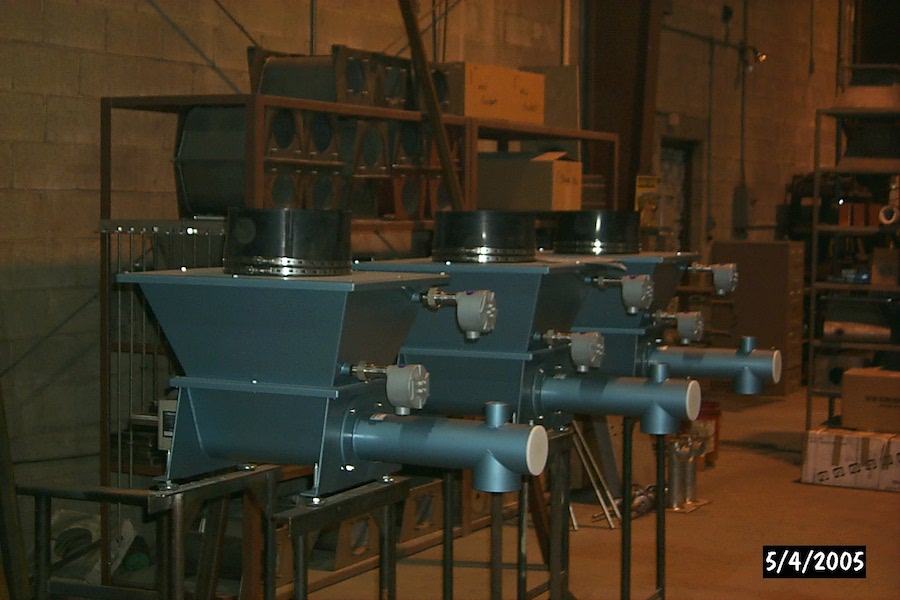

- Unique ability to integrate electro-mechanical components and programmable controls into a fully assembled and tested system (such as skid systems)

- Ability to work with a diversity of materials including: carbon steel, 304 and 316 stainless, high temperature 309 and 310 stainless, and abrasion-resistant AR400

- Engineer, supply, integrate, and program controls for multiple operating systems

- In-house Certified Welding Inspector and weld procedures certified to ASME-31.3 and AWS D1.1 and D1.6

- Project scheduling, monitoring, and reporting

Product Experience

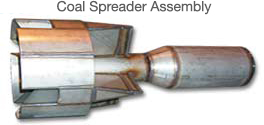

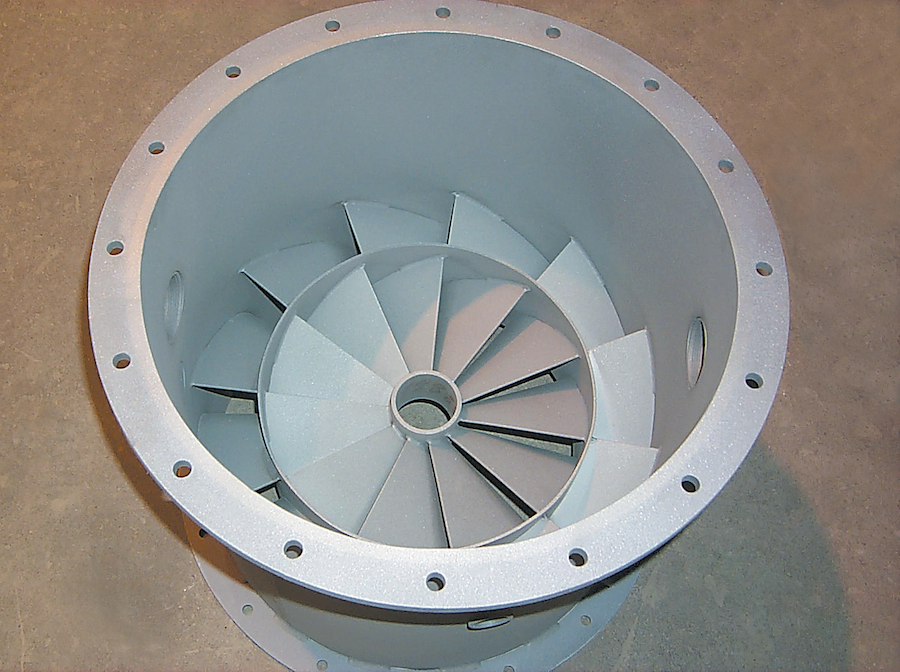

- Burner Modification Components

- Conveying Equipment

- Bulk Storage Bins

- Hoppers & Chutes

- Guards & Housings

- Dust Collectors & Electrostatic Precipitators

- Industrial Ductwork

- Weldments

- X-Ray Equipment

- Structural Fabrications

Available Shop Equipment

- Shear Capacity: 3/8" x 120" long, HRSM

1/4" x 120" long, S/S - Brake Forming: LVC CNC 3/8" x 10' long, 240 tons

Chicago 14 gauge x 8' long, 49 tons - Punching & Burning: AKS Hi Definition CNC plasma programmable burning with 72" x 120" cutting table. Maching capacity 1" thick carbon and stainless steet

90 ton ironworker

70 ton beam punch

40 ton station punch - Rolling: Roundo 5/16" x 10' durable pinch plate roll

- Cutting: Marvel 18A automatic feed 220" square

Marvel 8, 18" square

Abrasive cutoff saw 16" - Welding: (14) MIG, (4) TIG, (2) spot, (5) arc

- Crane Capacity: (1) 5 ton, (1) 4 ton, (1) 3-1/2 ton, (1) 2 ton and (8) jib cranes

- Forklift: (1) 12,000 lb. capacity, (1) 6,000 lb. capacity

- Trucking: (1) 20' flatbed w/ 20,000 capacity

Activated Carbon Injection

Activated Carbon Injection Dry Solids Processing

Dry Solids Processing Custom Fabrication

Custom Fabrication

Website

Website